CKD’s technology recognized in Japan and around the world

- Home

- CKD TECHNOLOGY

- Component Products

Pneumatic components

Practical pneumatic technology that meets the needs of a wide range of industrial fields

CKD’s product lineup fulfills fluid control, hygiene management, environmental protection and energy-saving needs. CKD has increased the variety of peripheral system components by developing clean air systems and auxiliary pneumatic components such as “FRL Units” and “Air Dryers.” We also have extensive drive components such as pneumatic cylinders and electric actuators.

Fluid control components

High quality and wide variations.

CKD provides the fluid control system best-suited for the purpose.

With a theme of “High Quality & Wide Variation,” CKD develops units and systems for controlling and effectively using conveyable media such as water, air, gas, steam, oil, etc.

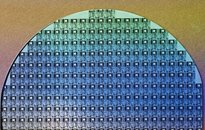

Fine system components

Exceedingly high purity and high precision.

CKD works with cutting-edge technologies in ultra-clean environments.

The industry of semiconductors and liquid crystals requires control components that can be used in an ultra-clean environment. CKD is striving for “Ultra High Level Process Control” to ensure the high precision and high performance of semiconductor-related equipment from the supply systems to the exhaust systems, such as “chemicals control components,” “process gas control components,” and “high vacuum control components.”

Labor-saving components

Super-effective automatic drive systems

at the various stages of production sites, e.g., processing, assembly, conveyance, etc.

CKD’s labor-saving components reflect our original perspective and technological strengths under a theme “higher precision, faster operation and lower costs.” These products are based on customer needs. We have an extended series of labor-saving components to meet various requirements for control, output, rigidity, speed and smoothness.